twin

Virtual commissioning • Simulation • Optimization

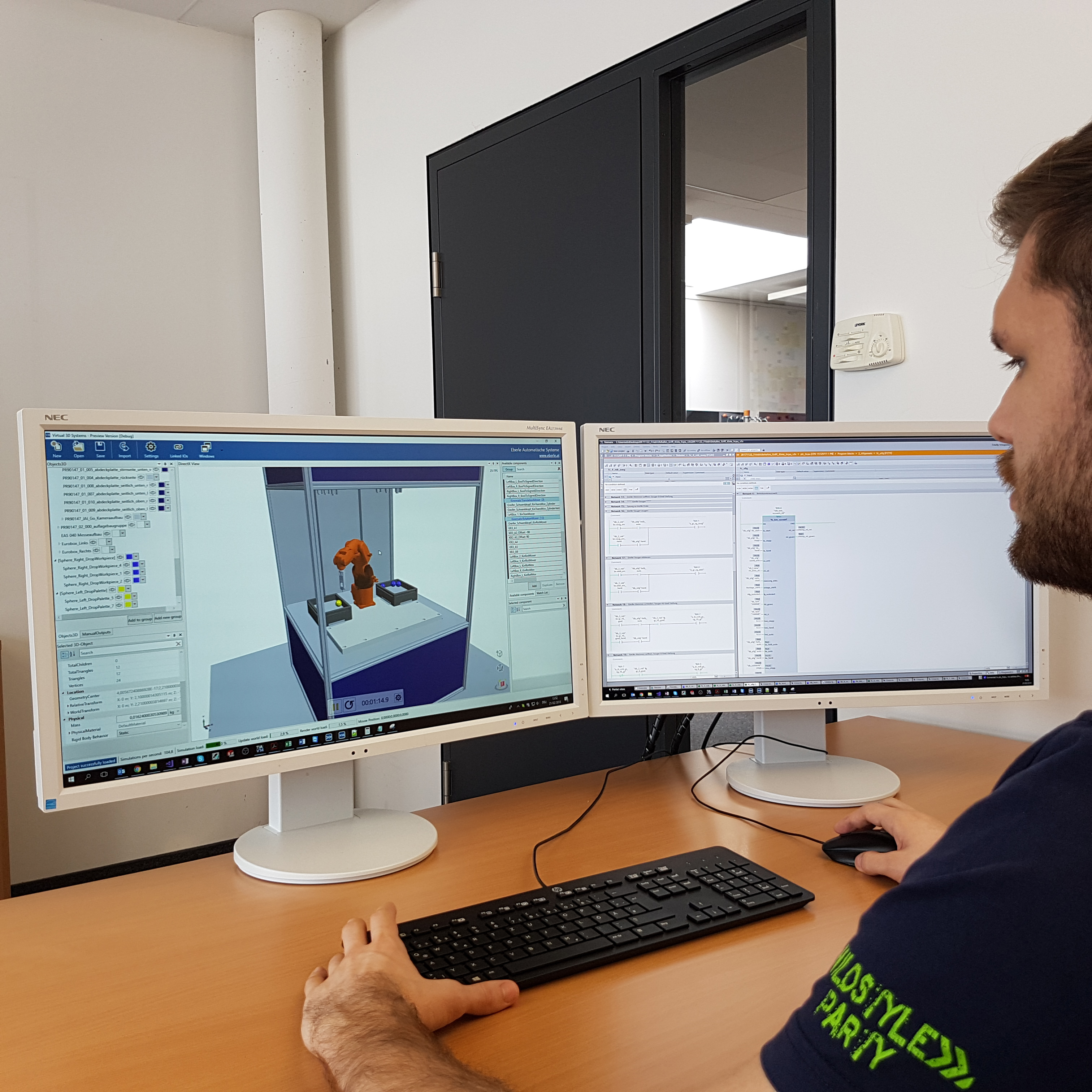

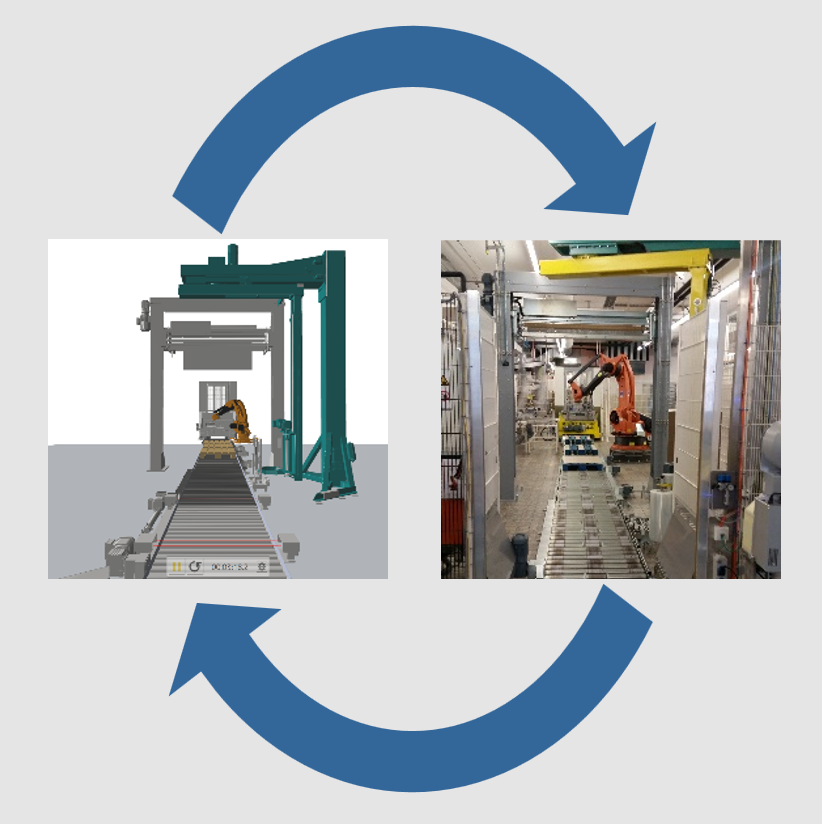

The development of special purpose machines takes on a new dimension with the simulation software twin. Real parameters are developed, tested and put into operation in a virtual, animated 3D environment.

Developments with twin are efficient, digital and recyclable. twin increases the benefits of assets and minimizes time spent on development. With the simulation software twin, digital twins become real in no time!

The simulation software twin is online! More information about the product as well as the topics virtual commissioning, digital twins, simulation and model-based PLC programming can be found at www.digifai.com.

twin

Intuitive development in a new dimension

The simulation software twin opens up new horizons in the development of sequence controls for mechanical engineering.

Already in the design phase, actuators and sensors are mapped with real data. PLC programs are developed on the model and continuously tested. Collision points of machine components and workpieces become immediately visible and flow into the development process. Later, twin is the core of the real Human Machine Interface. Based on the integrated 3D animation, the HMI is fully tested.

Sources of error are localized and excluded in advance. The test phase is thus an integral part of the development and ensures the results.

twin is the new dimension in the development of machine controls!

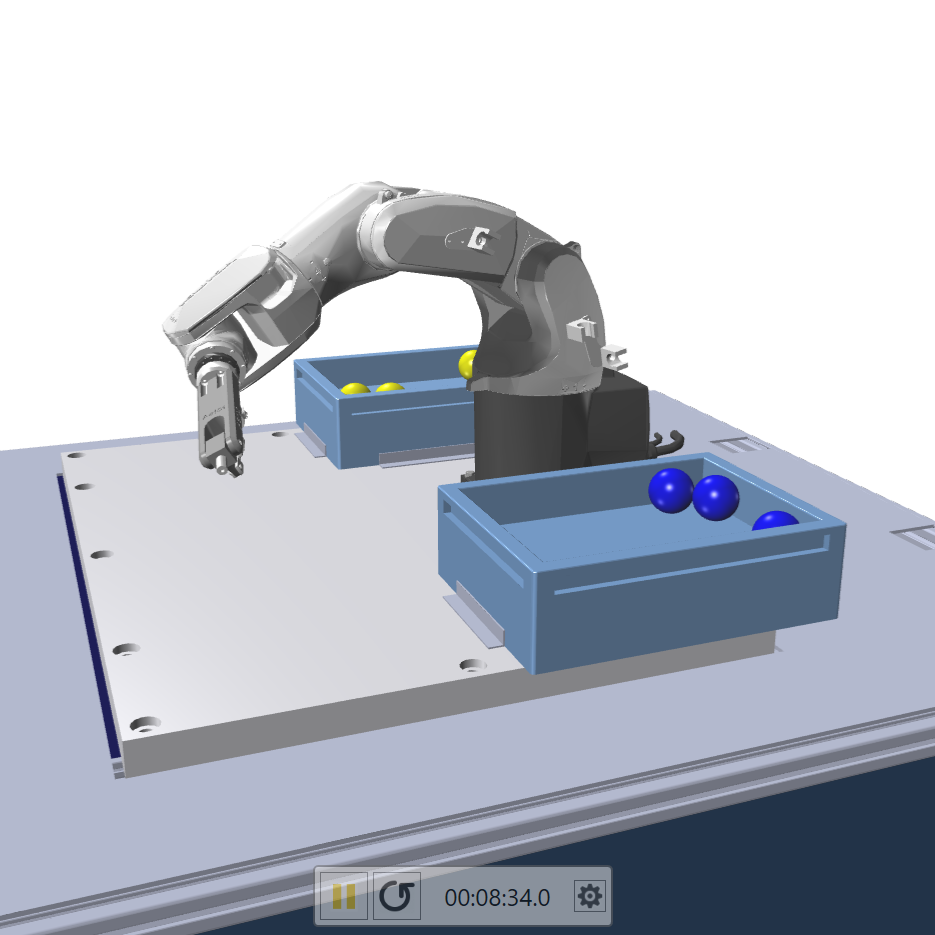

Overlapping and realistic animation

twin enables a fully comprehensive and cross-area animation in real time. The complete sequence with the different cycle times of machines and logistics equipment is shown in the animation. This level of detail gives a realistic view of the future automation solution and provides information about the performance of the planned investment.

Virtual development makes it possible to test actuators and sensors. In the animation, new program functions are continuously implemented and tested independently of the mechanical engineering. This enables a process-optimized design of the control system.

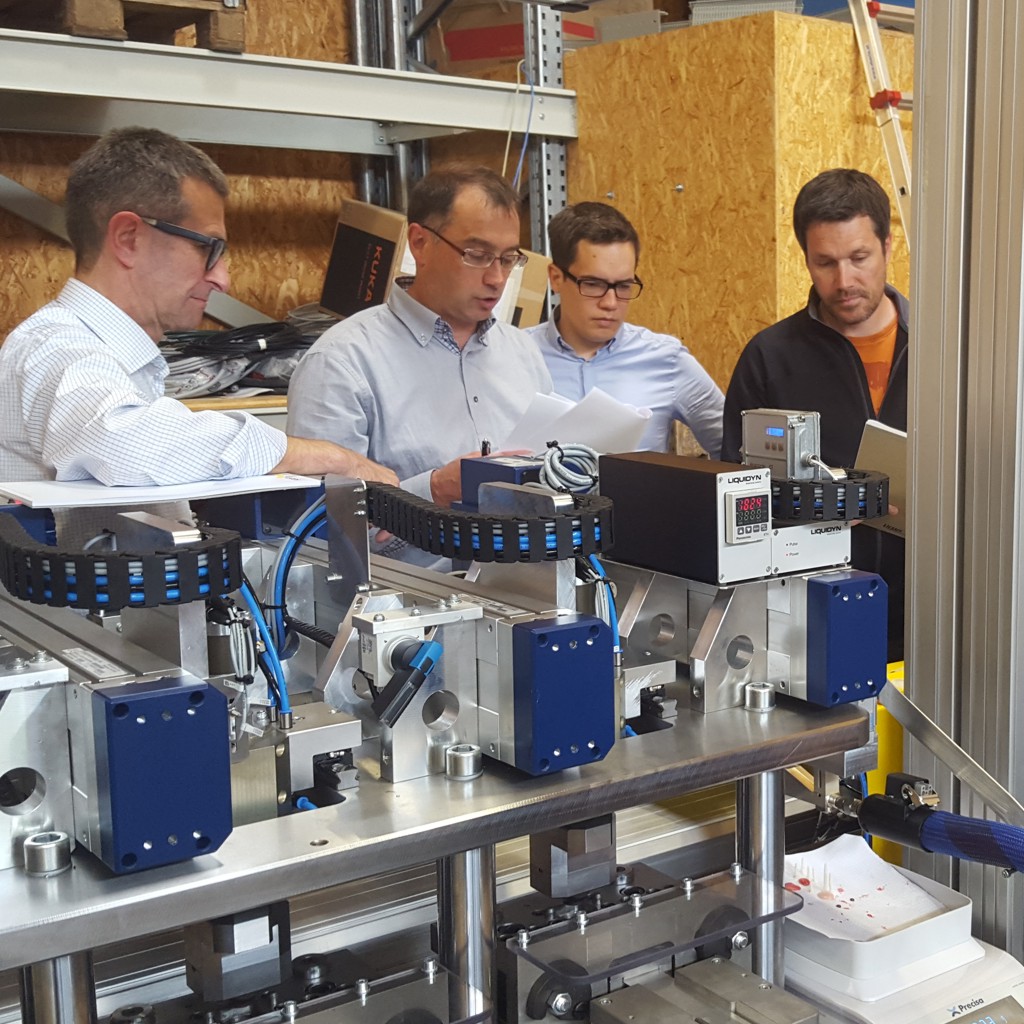

Everyone benefits from virtual commissioning

Machines developed with twin simulation software get up and running faster. The programming and commissioning phase is shifted from the end of development to its beginning. twin increases competitiveness throughout the value chain.

Virtual commissioning brings independence from hardware installation. Mechanical engineering can already test the processes during production and take necessary changes into account.

Training for users and operating personnel already begins on the animated model. The commissioning itself is reduced to a minimum.

Expenses for commissioning, travel costs and working time are significantly reduced. On average, twin shortens the entire development process by 30% compared to conventional methods.

The software arrives at the plant already tested and now acts as quality control for the hardware design.

On-site conversion phases are significantly shortened and the associated disruptions to ongoing operations reduced.

Added value without effort

The fully animated 3D model is used as HMI on the real machine. In ordered structures, complete integration into the control level takes place.

During operation, twin brings further advantages: Maintenance is greatly simplified by the combination of 3D model and real machine. Based on the feedback of machine data to the model, forecasts are generated. In the event of a fault, the analysis is already carried out on the digital twin and the service technician can carry out targeted repair work. This guarantees a high level of reliability and stable operation of machines and systems.

For product adaptations, changes to the parameterization are first made and tested on the 3D model. At the push of a button, the machine is then converted during operation. This in turn is one of the basic prerequisites for the smart factory concepts of Industry 4.0.

Digital recycling

The complete mapping of a machine in twin with the real program and real parameters enables further development in the virtual world. For new plants to be designed, the modules of existing machines can be adopted.

With twin’s platform technology, machines and plants can be reproduced virtually. The digital twin is the basis for future machine generations. Thus, twin-based developments have a sustainable starting advantage.

twin provides the ideal environment for testing updates in advance. This eliminates expensive downtimes and possible damage.

The recycling of existing systems and machines increases their useful life. Investments become more economical with twin.