Retrofit using the example of a CIP system control in a brewery

The private brewery Höß GmbH & Co. KG (Der Hirschbräu) from Sonthofen recently decided on and implemented a retrofit of the existing CIP system control. Eberle Automatische Systeme GmbH & Co KG from Dornbirn was responsible for the design, programming of the control system and ultimately also the implementation and commissioning.

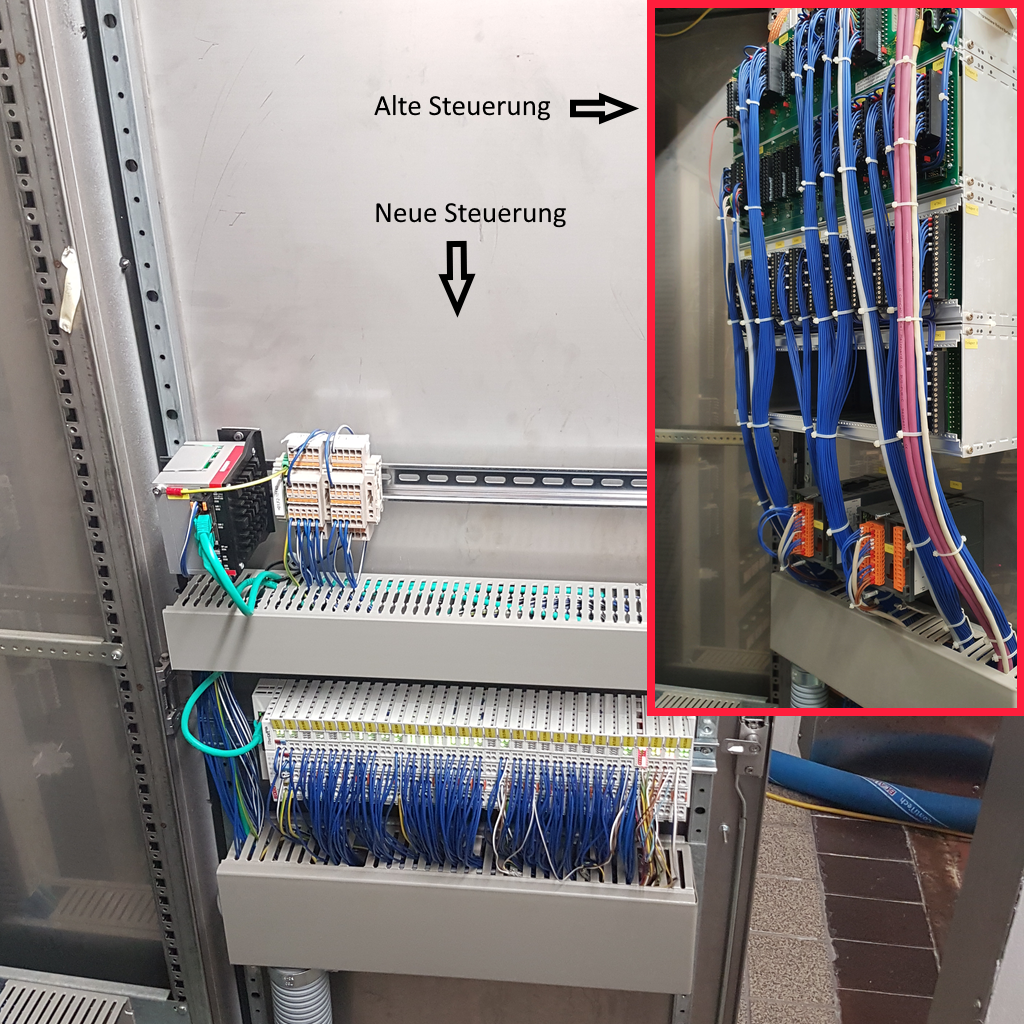

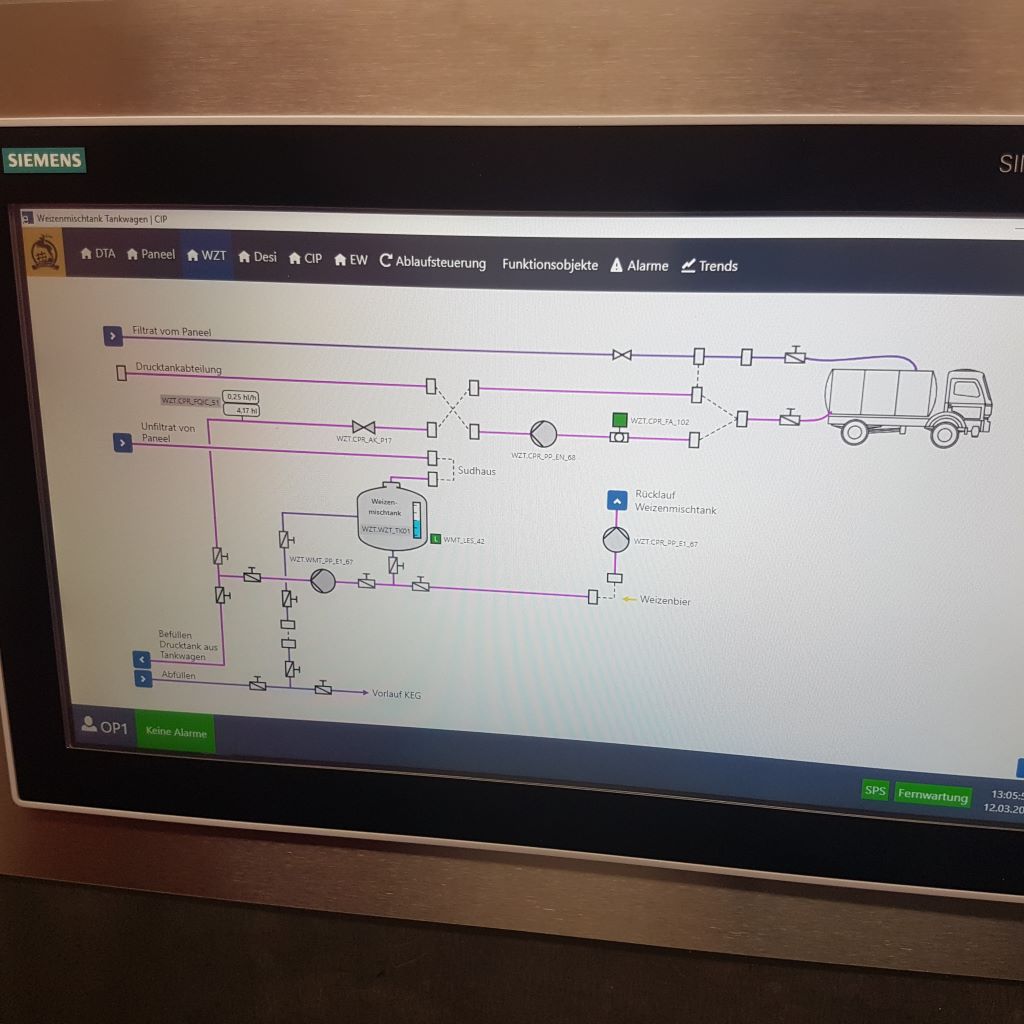

The existing CIP system was getting on in years. However, the mechanics and pipework were still intact and did not need to be replaced. There was therefore a need for action on the control system. Furthermore, the conversion was to take place without any major interruption to operations. The existing control system was converted to a completely new PLC-based control system and equipped with a user-friendly web-based user interface. The latter also allows the brewmaster to view the system from his desktop PC. The existing hardware components, including the control cabinet, were retained.

We would like to thank Privatbrauerei Höß GmbH & Co. KG for their trust, the order and especially for the good co-operation. The project report deals specifically with the subject of retrofitting as well as the associated advantages and challenges.

Is there an expiry date for old control systems and why do a retrofit at all?

There are various reasons for carrying out a retrofit, or quite simply necessities. The end of operation for machines and systems is not marked by an expiry date, as is the case with foodstuffs, apart from an operating licence that has expired. In the case of technical equipment, machines and systems, other criteria are decisive that require a new acquisition or a retrofit.

– Plant failures occur more frequently and lead to more downtime or the threat of total failure

– Spare parts for the existing machine or system are no longer available or are difficult to obtain

– The manufacturers of the replaceable system components no longer offer a replacement or successor or the suppliers no longer exist

– The software used in the system is no longer up-to-date or can no longer be updated

– The technicians and service staff have to painstakingly familiarise themselves with the requirements of the outdated technology in the event of faults or require special tools and software that are no longer available

– Continued operation of the system or machine in its existing form would mean high production costs due to personnel, energy or reduced production output

– The existing system or machine can no longer keep pace due to increased requirements or higher output performance of upstream processes

A retrofit can also be described as an efficient new start. Compared to a new acquisition, there are no lengthy evaluation phases and in-depth analyses of different vendor solutions. A new acquisition can also be associated with spatial or process-related reorganisation measures. With a retrofit, this is usually not necessary or is much less extensive than with a new acquisition. A well-considered retrofit has advantages over new acquisitions.

– Experience gained from operating the old automation system can be better adapted to the automation system with a retrofit than with standardised new systems

– If the application permits, the retrofit can also be carried out in stages

– The mechanics hardly become obsolete and can continue to be used with a retrofit

– A retrofit of the control components brings old systems and machines into the networked age of IoT. This often solves the interface problem for exchanging data from existing automation systems

– After the retrofit, serviceability and spare parts availability are ensured again

– The retrofit is often associated with system tuning to increase efficiency

– Reuse or continued use is clearly sustainable

– The conversion and retrofit can be planned

– Less staff training required. Employees do not require training or further training for new systems

Whether a retrofit or a new acquisition is an option, however, must be decided on a case-by-case basis.

The right preparation for a retrofit

Once the decision has been made in favour of a retrofit, it must be prepared accordingly. Ultimately, a retrofit usually means a conversion during ongoing operations or in a production environment. Thorough preparation and detailed planning are essential for successful implementation. Similar to open heart surgery. The first step is a detailed inventory. All data must be recorded, the existing solution inspected and, if necessary, supplemented with tests and measurements. Everything that is forgotten or carelessly ignored during the inventory must later be painstakingly incorporated into the implementation planning or execution, or is simply forgotten. Existing documentation such as circuit diagrams, function layouts and programmes must be viewed and understood. Experience with retrofitting is an advantage here in order to correctly assess the condition of the machine. The development status of the installed components must be recorded in detail in order to have a basis for making decisions on the replacement of individual components for the implementation.

With a retrofit, the system or machine is harmonised with the current normative and legal requirements. The existing safety devices must be checked and supplemented if necessary. A re-evaluation or risk analysis may be necessary for particularly critical applications. From a business point of view, it is advisable to keep a preliminary risk assessment up to date by carrying out a cost-benefit analysis during the design phase.

Digital tools and simulation help to prepare the retrofit and identify risks at an early stage before implementation. Processes and programmes can be tested virtually on the digital twin, for example with twin. For example, the PLC programme of the control system is developed and tested in advance on the digital twin before it is used in the course of the retrofit. It is then very easy to make and test changes to the virtual model before it is actually put into practice with the retrofit.

How is professional implementation carried out?

Before implementation, the framework conditions for the retrofit must be clear. Will the retrofit be carried out during a non-operational period? Will the retrofit be carried out in stages? Can updates be cancelled if necessary?

As soon as the key data is known, resources and material deliveries are planned and scheduled. The less time is available for the remodelling, the more must be invested in the planning. Thanks to modular software and hardware, it is still possible to react flexibly to unforeseen events during the remodelling phase. The rest is the consistent realisation of the planning. The expected behaviour is already known and tested from the planning and simulation with the digital twin. This makes the hardware conversion much easier, reduces unforeseen risks and saves valuable time.

What optimisation is possible with a retrofit?

A retrofit can and should be accompanied by an optimisation of the existing system or machine. Retrofits make it possible.

– Get rid of existing malfunctions and weak points

– Add desired functions

– Simplify the operation of the machine or system or improve its ergonomics

– Make the new programming more flexible and scalable

– Save energy, for example through new or energy-optimised drives

– Create modern interfaces for networking

Previous experience from the process can be optimally utilised in retrofits. This makes retrofits particularly interesting.

Modern automation is networked and has mobile monitoring

With a retrofit of the control system, the machine or system is also up to date with the latest developments. This means that networked applications, as required by Industry 4.0, are easy to implement. Modern control systems offer the necessary data interfaces and record all signals and measured values in the process with the connected sensors. Networking with IoT platforms such as control means that the recording of operating and machine data is automated and does not have to be created manually. The data collected and archived makes it much easier to trace and analyse processes in machines or systems. Continuous data recording and monitoring also makes it possible to intervene at an early stage in the event of undesirable developments. Data-based maintenance management makes maintenance much easier. An IoT platform also makes it easier to monitor machines and systems and enables process values to be viewed remotely via mobile devices.

Retrofits make the user interface easier to understand with clear symbols and clear categorisations. The new user interface can be linked to the digital twin from the planning and you get a realistic 3D visualisation of the machine or system. This makes operation considerably easier. A further simplification is the WEB technology which, for example, also enables access to the user interface from workstation desktop PCs.

Sustainable through retrofitting

Retrofits are inherently more sustainable than new purchases. Because ‘new’ always means that it has to be produced again. Existing and reusable material does not have to be produced again. This eases the burden on the recycling process. The transport costs for a retrofit are much lower than for new purchases. However, energy consumption during operation must also be considered in the overall assessment. In the ideal case of a retrofit, energy consumption is also reduced, for example through the use of optimised drive components. Modern control systems can better balance energy consumption and the energy supply from their own sustainable energy sources, provided this is possible in the process.

After a retrofit, the system or machine can be operated more economically. An optimised system produces more productively with fewer rejects and better quality. The life cycle is extended by a retrofit. The original investment in the machine can continue to generate added value long after it has been amortised. Factory buildings and machine foundations do not have to be adapted to new systems or machines. This saves money, time, nerves and energy.

A retrofit is due or desirable for a machine or system – how should you proceed?

The procedure for a retrofit must always be tailored to the existing system. However, there are basic steps and procedures that must be observed in retrofit projects.

1. check what is defective and what should or can be retained?

2. are spare parts still available for the existing system? What is the availability of spare parts? How long does the supplier guarantee availability?

3. involve the plant manufacturer or automation engineer at an early stage

4. is the machine or system still producing economically? Is an increase in output performance necessary in the future?

5. how could the conversion be carried out? Is a conversion necessary during ongoing operation or are there plannable non-operating times?

6. summarise feasibility and costs as a basis for decision-making – the digital twin helps here